-

Automatic Frequency Tracking Ultrasonic Welding Machine

HC-2020/HC-1526

Send Email Details

1. Original imported piezoelectric ceramic transducer, strong and stable output.

2. Anti-tilt and coaxial direct pressure design, balanced pressure application, improved welding precision.

3. LCD digital welding parameter setting, intuitive and accurate.

4. Microcomputer program control system, welding time 0.01-19.99S precise time control.

5. All main electrical components, high-quality imported parts assembly -

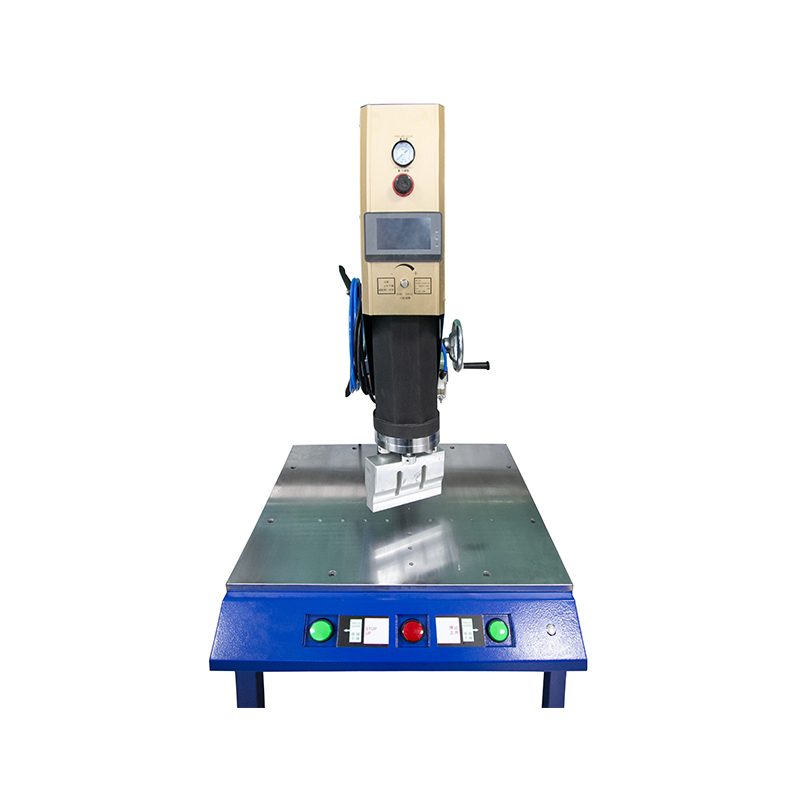

Automatic Frequency Tracking Ultrasonic Welding Machine With Workbench

HC-2020/HC-1526

Send Email Details

1. Original imported piezoelectric ceramic transducer, strong and stable output.

2. Anti-recoil and coaxial direct pressure design, balanced pressure application, improved welding precision.

3. LCD digital welding parameter setting, intuitive and accurate.

4. Microcomputer program control system, welding time 0.01-19.99S precise time control.

5. All major electrical components, high-quality imported parts assembly

6. Suitable for large products, easy to move the machine -

Precision Ultrasonic Welding Machine

HC-2020/HC-1526

Send Email Details

■Complete machine CNC machining, high precision, high welding efficiency, low defect rate

■Improved circuit, automatic frequency compensation circuit, overcurrent, overvoltage, phase protection circuit

■Original Japanese piezoelectric ceramic transducer, strong and stable output

■Titanium alloy amplitude transformer, sturdy and durable

■Square column, linear slide guide, precision fine-tuning device

■Adjustable bottom plate structure, convenient and quick mold debugging

■Split structure to avoid dry pulling

■Assembled with all high-quality imported parts, quality assurance -

High Power Ultrasonic Welding Machine

HC-1542/HC-1560

Send Email Details

Applicable to: drying drums, ink cartridges, car dashboards, headlights, taillights, car filters, etc., welding of larger products.

Product Description:

1. Japanese NTK series transducer, strong power and good stability.

2. The body is designed with anti-backward and coaxial direct pressure, and the pressure is evenly applied to improve the welding precision.

3. 4200W power output, suitable for welding of larger plastic products, with good welding effect.

4. The main electrical components and parts are assembled with high-quality imported parts.

5. The unique horizontal screw design makes the mold easy to debug.

6. Ingenious structure, reasonable design and beautiful appearance. -

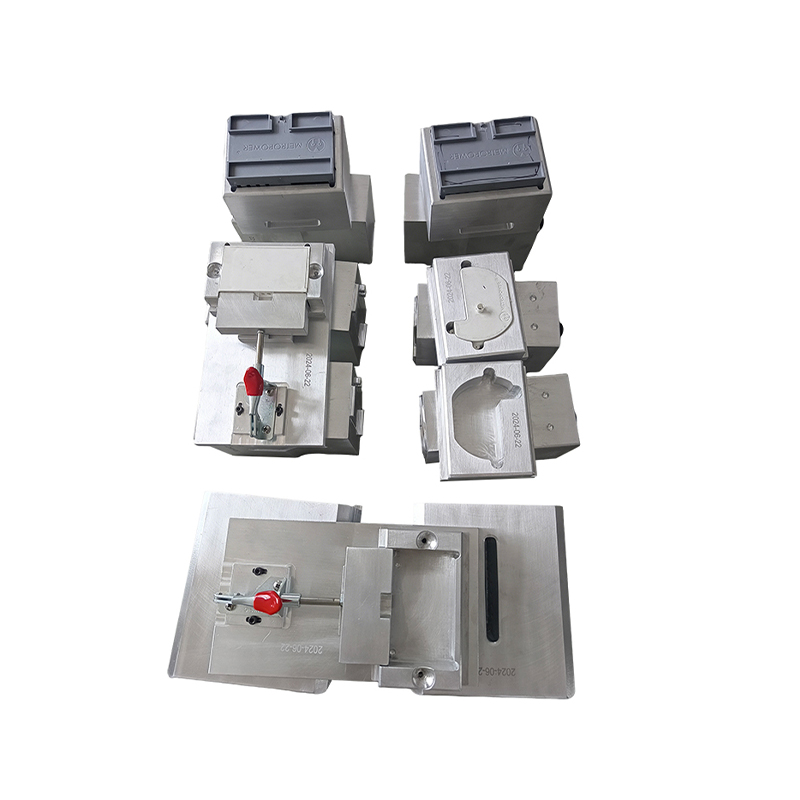

Ultrasonic Mold

Customized

Send Email Details

Ultrasonic Mold

1. Customized molds of various frequencies according to customer requirements.

2. Made of imported aluminum alloy materials, CNC engraving and processing.

3. Professional software analysis to extend the service life of the mold and enhance the welding effect.

Ultrasonic welding processing

Processing and welding of materials according to customer needs.