-

Ultrasonic Nozzle Separator

Advantages of Ultrasonic Water Spout Separator

Send Email Details

Modern large-scale machine production has gradually replaced manual labor. Ultrasonic water outlet separator is a very good machine equipment, which can greatly improve work efficiency. It has the characteristics of high cutting accuracy, high cutting precision and environmental protection. Compared with the previous cutting mode, this cutting mode can meet production needs in a very short time. The ultrasonic water outlet separator produced by Huacheng Ultrasonic is of reliable quality, and the company has a complete technical service team, which can provide you with good technical support.

The application scope of ultrasonic water outlet separator is very wide, mainly suitable for the processing and production of hard thermoplastic plastics, such as polyethylene, Milong, ABS, PC, AS and other materials. The workpieces processed and produced by ultrasonic water outlet separator have many advantages, such as smooth cut, practicality and consistency, and the appearance is very good.

The application scope of ultrasonic water outlet separator is very wide, suitable for many fields of application. When buying, you should pay attention to buying a model that meets your needs. -

Servo Hot Melt Welding Machine And Mold

Servo hot melt welding machineThe servo hot melt machine adopts a drawer structure, and uses electric heating to transfer the heat of the heating plate to the welding surface of the upper and lower plastic heating parts. The surface is melted, and then the heating plate is quickly withdrawn. After the upper and lower heating parts are heated, the molten surfaces are fused, solidified, and combined into one. The whole machine is in the form of a frame, consisting of three plates: the upper template, the lower template, and the hot template. It is equipped with a hot mold and upper and lower plastic cold molds, and the action mode is servo control.The heating power and mold size can be set according to the size of different plastic parts to achieve welding of various plastic workpieces. It is simple to operate and easy to use. The heating plate consists of two upper and lower pieces, which are heated by electric heating pipes. There are two temperature controllers to control the temperature of the upper and lower molds respectively. When welding, it can be set within the range of 0 to 600°C according to the actual needs of welding.Hot melt welding machine is suitable for car lights, car water tanks, washing machine water faucets, car doors, dashboards, central control, air ducts, plastic water tanks, oil pots, lamps, containers, car water tanks, washing machine water faucets, batteries, steam irons, car plastic fuel tanks, batteries, taillights, dashboards, air intake pipes, plastic pallets, carbon cans, brake fluid tanks, bumpers, instrument panels, exhaust purifiers, batteries, motorcycle asphalt cleaners, washing machine plastic balance rings, washing machine drums, dishwasher water tanks, steam irons, foot baths, etc.Send Email Details -

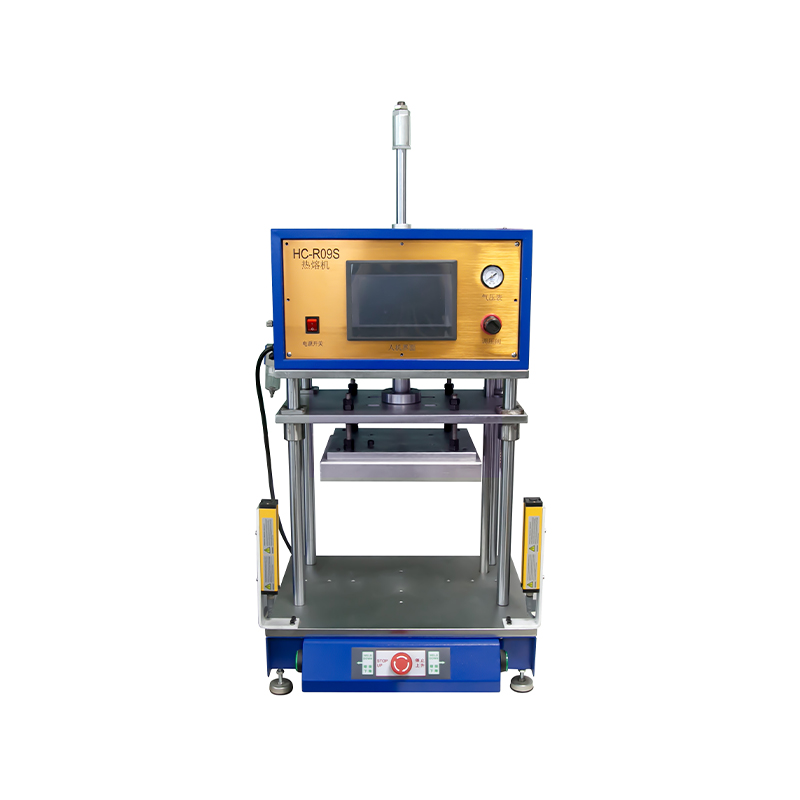

Standard Hot Melt Welding Machine

The HC-R09 hot melt machine adopts a pull plate structure, and the heat of the heating plate is transferred to the welding surface of the upper and lower plastic heating parts by electric heating. The surface melts, the heating plate is quickly retracted, and the upper and lower molten surfaces are fused, solidified and integrated. The whole machine is frame-type, consisting of three plates: the upper template, the lower template, and the hot template, and is equipped with a hot mold, upper and lower plastic cold molds, and the action mode is pneumatic control.

Send Email Details

According to the different sizes of plastic parts, the heating power and mold size are set to achieve various plastic parts welding, which is simple to operate and easy to use. The heating plate consists of two upper and lower parts, which are heated by electric heating pipes. Two temperature controllers are set to control the temperature of the upper and lower molds respectively. In the range of 0~600℃, the welding time can be set according to actual needs.

The HC-R09 hot melt machine is suitable for hot melt welding of small products, such as tablets, mobile phones, copper nut implants, etc. -

Spin Welding Machine

Typical applications

Send Email Details

Spin welding is widely used in round plastic parts that require high-strength sealing, such as:

• Filter element: household water purifier filter element, industrial filter element, activated carbon filter element.

• Automotive parts: oil cup, air duct, carburetor, etc.

• Daily necessities: double-layer cup, thermos cup, float, dehydration container, etc.

Equipment type

According to needs, you can choose a positioning spin welding machine or a non-positioning spin welding machine. The former uses a servo motor to achieve high-precision angle control, which is suitable for complex alignment scenarios.