News

-

How does an automatic frequency tracking ultrasonic welding machine achieve precise frequency matching?

In actual welding, factors such as material deformation and welding head wear can cause changes in system impedance, which in turn can lead to frequency drift.

Learn More2025-12-01 -

How to avoid cracks or pores in the weld area when using a spin welding machine?

During spin welding, parameters such as current, voltage, and welding speed directly affect the shape of the molten pool and the conditions for gas escape.

Learn More2025-11-17 -

How does an automatic frequency tracking ultrasonic welding machine adjust the frequency in real time to match load changes?

During the welding process, the increased temperature of the transducer and mold can cause changes in the elastic modulus of the material, which in turn can lead to frequency drift.

Learn More2025-11-03 -

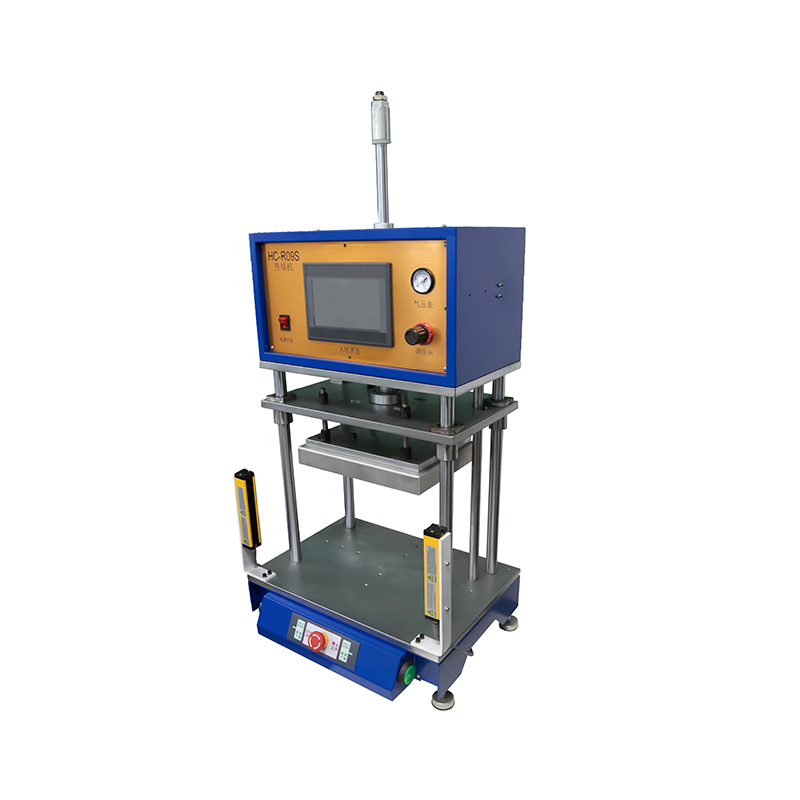

How does a hot melt welding machine ensure secure and leak-free pipe joints?

In modern water supply, drainage, gas, and HVAC projects, the safety and durability of piping systems are paramount.

Learn More2025-10-20 -

How much influence does the spindle rotation drive accuracy of the spin welding machine have on the welding quality?

During the welding process, the molten pool is in a dynamic equilibrium state of liquid metal, and slight vibration or speed fluctuation of the spindle will destroy this balance.

Learn More2025-10-08 -

How to prevent deformation and burn-through when welding thin-walled parts with spin welding machine?

After welding, rigid components need to be tempered before disassembly and assembly to avoid deformation caused by residual stress release.

Learn More2025-09-25